News

Search all news

ANL and Aurizon partner on Landbridging through Darwin

ANL, a renowned shipping company with a rich history in Australia and the Oceania region and Australia’s largest rail freight company Aurizon have partnered on a landbridging supply chain solution for Asia Pacific container traffic through the Port of Darwin.

Latest news

Empower your community: apply for Aurizon's Community Giving Fund today

17 Mar 2025

ANL and Aurizon partner on Landbridging through Darwin

17 Feb 2025

Aurizon's Community Giving Fund: Supporting local initiatives

17 Dec 2024

Approval for acquisition of Flinders Logistics

28 Nov 2024

First train hits the tracks for Gold Valley

04 Oct 2024

What could you do with a cash grant from Aurizon’s Community Giving Fund?

16 Sep 2024

Aurizon and Mackay Council partner on native reforestation project

04 Sep 2024

Aurizon’s Community Giving Fund: empowering local initiatives and enriching lives

26 Jun 2024

New national campaign for level crossing safety

06 Jun 2024

Stories

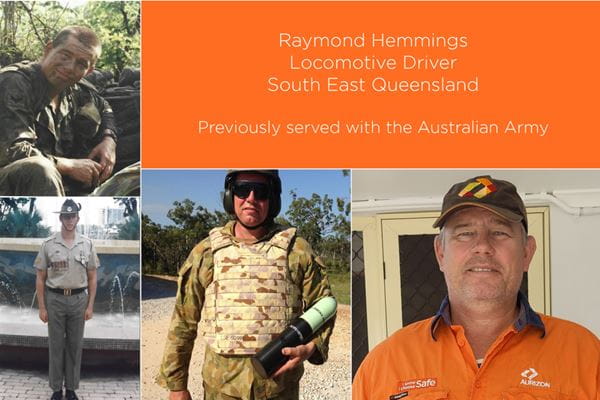

Anzac Day - Honouring 110 Years of Sacrifice and Service

23 Apr 2025

Train driver Lauren Blake shares her story as part of National Rail Safety Week

09 Aug 2024

Train driver Hamish Withington shares his story as part of National Rail Safety Week

05 Aug 2024

Celebrating our First Nations people

27 May 2024

Anzac Day - A day of reflection and gratitude for our veterans

24 Apr 2024

Leading the way in technological innovation

08 Mar 2024

Celebrating NAIDOC Week with Jacob White

04 Jul 2023

Aurizon’s Caitlyn Gallagher shares her story as part of National Reconciliation Week

01 Jun 2023

Commemorating our veterans on Anzac Day

24 Apr 2023